Unlocking the Secrets of Remote I/O Modules: Your Gateway to Smarter Industrial Automation

In today's fast-paced industrial landscape, the demand for efficient data management and automation is at an all-time high. One of the unsung heroes of this movement is the remote I/O module. These devices play a crucial role in streamlining operations by enabling the seamless communication between sensors, actuators, and control systems. As industries transition toward more automated processes, understanding the function and significance of remote I/O modules becomes paramount. This article will delve into what these modules are, how they operate, and their myriad applications across various sectors, ultimately highlighting their importance in modern industrial automation.

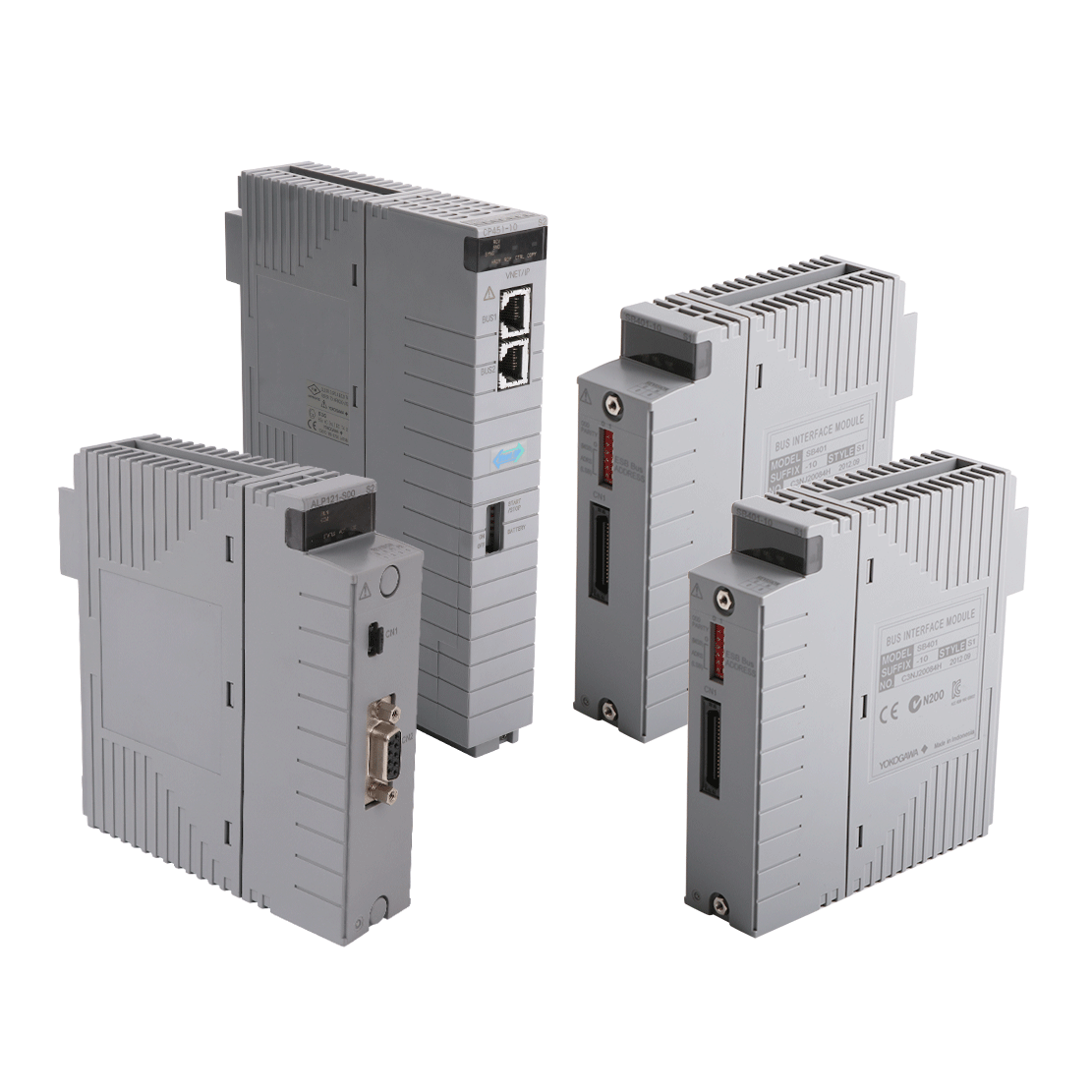

Understanding Remote I/O Modules

Remote I/O modules are specialized devices designed to facilitate communication between field devices (such as sensors and actuators) and a central control system. They serve as an interface, allowing data from various sources to be gathered and transmitted effectively. Typically, a remote I/O module consists of several key components, including input/output channels, communication ports, and a power supply. The inputs and outputs can be digital or analog, depending on the requirements of the application. By placing these modules closer to the field devices, industries can reduce wiring clutter and improve the overall efficiency of their systems, making them an essential component in the realm of industrial automation.

How Remote I/O Modules Function

The operational principles of remote I/O modules are built on effective data transmission and communication protocols. These modules typically connect to a central controller via network protocols such as Ethernet, Modbus, or CAN bus. Data transmission occurs in two primary formats: digital signals, which are used for on/off operations, and analog signals, which provide continuous data representations. When a sensor detects a change in the environment, it sends a signal to the remote I/O module, which processes the information and forwards it to the central control system. This process ensures real-time monitoring and control, enabling industries to react swiftly to fluctuations in operational parameters. The flexibility in communication protocols allows these modules to be integrated into various systems, making them versatile for diverse industrial applications.

Applications of Remote I/O Modules in Industrial Automation

Remote I/O modules find applications across a wide range of industries, including manufacturing, energy, and transportation. In manufacturing, for instance, they play a pivotal role in monitoring production lines by connecting various sensors that track machine performance and product quality. A friend of mine who works in a manufacturing plant shared how the integration of remote I/O modules significantly reduced downtime by enabling instant alerts when machinery requires maintenance. In the energy sector, these modules assist in monitoring and controlling renewable energy sources, like solar panels and wind turbines, by providing real-time data to optimize performance. Similarly, in transportation, remote I/O modules enhance the reliability of traffic management systems by collecting data from various sensors, ensuring efficient flow and safety. From predictive maintenance to process optimization, the applications of remote I/O modules are diverse and impactful.

Benefits of Implementing Remote I/O Modules

The implementation of remote I/O modules brings numerous advantages to industrial operations. One significant benefit is improved scalability; as businesses grow, they can easily add more modules to expand their system without extensive rewiring. This adaptability is particularly beneficial for companies that frequently modify their operational setup. Additionally, remote I/O modules substantially reduce wiring costs, as they minimize the need for lengthy cable runs between the control system and field devices. Another key advantage is enhanced system monitoring capabilities; with the real-time data provided by these modules, operators can make informed decisions quickly, ultimately leading to increased productivity and reduced operational risks. The combination of these benefits positions remote I/O modules as a vital component in the pursuit of smarter, more efficient industrial automation.

The Essential Role of Remote I/O Modules in Automation

Remote I/O modules are instrumental in shaping the future of industrial automation. From their fundamental role in connecting sensors and control systems to their diverse applications across various sectors, these modules are essential for enhancing efficiency and reliability. As industries continue to evolve and embrace automation, understanding and implementing remote I/O modules will become increasingly important. By considering their integration into future projects, businesses can not only streamline operations but also pave the way for innovative advancements in industrial technology.