Unlocking the Secrets of Variable Frequency Drives: Discover the Hidden Components That Power Your Performance!

In the ever-evolving landscape of modern industry, Variable Frequency Drives (VFDs) stand out as a pivotal technology that enhances the performance of electric motors. By enabling precise control over motor speed and torque, VFDs not only improve energy efficiency but also contribute to the longevity of equipment. Whether in manufacturing, HVAC systems, or renewable energy applications, VFDs play an indispensable role. Understanding the intricate components that make up these drives is essential for anyone looking to harness their full potential. This article aims to demystify the various components of VFDs, shedding light on their functions and interconnections, ultimately providing you with the knowledge to optimize motor performance.

Understanding Variable Frequency Drives

At its core, a Variable Frequency Drive is an electronic device that controls the speed and torque of an electric motor by varying the frequency and voltage of the power supplied to it. The operation of VFDs hinges on their ability to convert alternating current (AC) into direct current (DC) and then back into a modified AC form. This conversion process allows for fine-tuning of motor performance, making VFDs highly sought after in various sectors such as manufacturing, water treatment, and even food processing. The ability to adjust motor speed not only enhances operational efficiency but also leads to significant energy savings. As industries continue to adopt automation and smart technologies, the demand for VFDs has surged, marking them as a cornerstone in modern electrical systems.

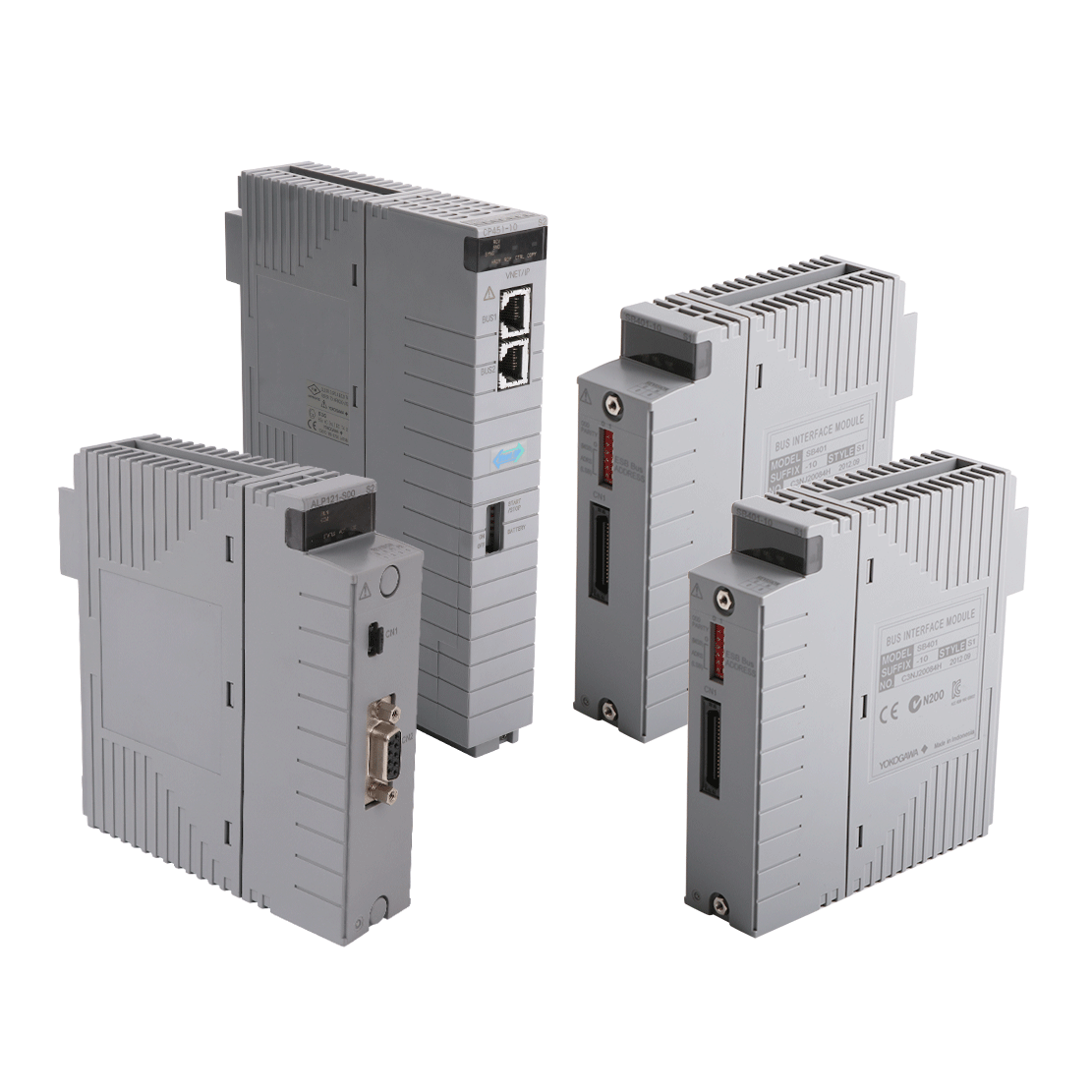

Key Components of Variable Frequency Drives

To fully appreciate the functionality of Variable Frequency Drives, it is crucial to understand their core components. A typical VFD consists of four primary parts: the rectifier, DC bus, inverter, and control unit. Each of these components works in concert to regulate motor performance effectively. The rectifier converts incoming AC voltage to DC, while the DC bus smooths and stores this power. The inverter then transforms the DC back into AC, adjusting the frequency and voltage as needed. Finally, the control unit orchestrates these operations, ensuring that the motor operates optimally based on real-time feedback. Together, these variable frequency drive components create a seamless flow of power that maximizes efficiency and performance.

Rectifier

The rectifier is the first major component in a VFD's architecture, playing a critical role in converting incoming AC power into DC power. By using diodes or thyristors, the rectifier allows only the positive half of the AC waveform to pass through, effectively eliminating the negative half. This conversion process is essential because VFDs operate on DC power internally before converting it back to AC. The efficiency of this component directly impacts the overall performance of the VFD, making it a vital consideration for design and selection.

DC Bus

Following the rectifier, the DC bus serves as a reservoir for the DC power generated. Its primary function is to smooth out fluctuations in the power supply, ensuring a stable voltage is delivered to the inverter. The DC bus typically includes capacitors that store energy, allowing for quick delivery of power when needed. This component is crucial for maintaining consistent performance, especially in applications that require rapid acceleration or deceleration of the motor.

Inverter

The inverter is perhaps the most critical component of a VFD, as it converts the stored DC power back into AC power. However, it does more than just inversion; it also modulates the frequency and voltage of the output to precisely control the motor's speed and torque. Using switching devices like transistors, the inverter generates a variable output frequency that allows for smooth acceleration and deceleration, preventing mechanical stress on the motor and connected machinery.

Control Unit

The control unit is the brain of the VFD, managing its overall operation. This component processes inputs from the user interface and feedback from the motor to optimize performance. It allows for programmable settings, enabling users to set parameters such as acceleration time, deceleration time, and maximum speed. Advanced control units may also incorporate features like PID control, which helps maintain desired performance levels under varying load conditions. The effectiveness of a VFD is heavily dependent on the sophistication of its control unit.

Benefits of Understanding VFD Components

Gaining a deeper understanding of the components within Variable Frequency Drives offers numerous benefits. For technicians and engineers, this knowledge is invaluable for troubleshooting and maintaining these systems. Recognizing how each component functions and interacts can lead to quicker diagnosis of issues and more effective repairs. Additionally, this understanding can facilitate optimization of motor performance, allowing users to adjust settings based on specific operational requirements. Ultimately, knowing the intricacies of VFD components empowers users to enhance energy efficiency, reduce downtime, and improve the overall reliability of their systems.

Maximizing the Potential of Variable Frequency Drives

In conclusion, Variable Frequency Drives are integral to modern industrial applications, offering enhanced control over electric motors. By understanding the key components—rectifier, DC bus, inverter, and control unit—users can unlock the full potential of these drives. This knowledge not only aids in troubleshooting and maintenance but also allows for optimization of performance and energy efficiency. As industries continue to evolve, the importance of mastering the components of VFDs cannot be overstated. Whether you are an engineer, technician, or simply an enthusiast, delving into the workings of Variable Frequency Drives will undoubtedly enhance your appreciation and understanding of this vital technology.